TOPSKY PRECISION MOULD LIMITED

Topsky is an mould manufacture company, located in bao’an area, shenzhen, with total area is 12000 squre meter. We specialize in a wide range of products such as automotive. appliance, electronics industry. Providing plastic injection mould proces and moulding parts service, Mainly serving the domestic and European, America market.

Our service

Topsky served in mould industry for many years, with the development, we have 20 ton lifter,

Equipment with 2.5M CNC machine and high speed CNC machine for processing complex and big mold component.

We work with small and large OEM's, custom molders contract manufacturers and developing companies all over the world which supply products to the business of Automotive, Consumer Electronics, Household appliances, Industry, etc.

Tooling

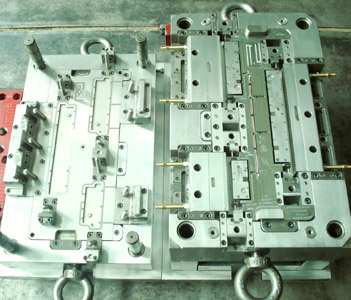

Topsky has a full set of tooling equipments, such as large-scale CNC machining center, EDM, wire Cut together with measure equipments, such as project, CMM. With continual investment in new manufacturing capabilities and constant drive to increase automation have resulted in improved mold quality and time to market.

We are experienced to design and manufacture big size molds for Automotive, Industrial parts. The maximum mold size we can made is up to 2.5M, mold weight 35T. All our molds are fully designed and manufactured base on the customer’s requirements.

Injection Molding

All molds manufactured by Topsky are fully tested to verify the specifications of molds and parts prior to shipment. During the test, our engineers record testing molding parameters and conditions. After the tests, mold trial reports together with full dimension report will be provided to the customers within 3 working days. Prior to serial-production.

We can also provide the production parts and assembled parts to our customer, our production system is in strict accordance with ISO9001 quality control procedures to ensure the products meet customer's requirements.